UV damage resistance ratings are essential for evaluating material durability in industries exposed to sunlight. These ratings assess a material's performance against UV radiation over time, considering degradation effects on chemical bonds, color, texture, and strength. Manufacturers use rigorous comparison testing under controlled conditions to simulate years of weather exposure, aiding consumers and professionals in selecting long-lasting materials. Intake system longevity is a critical but often overlooked factor; products with superior intake systems offer enhanced protection and extended use. Comprehensive UV testing methodologies involve simulating UV radiation exposure to analyze component degradation over time, enabling manufacturers to develop products designed for prolonged sun exposure.

“Discover the power of UV damage resistance ratings—a crucial factor in determining the lifespan of your materials. This article unravels the complexities of UV protection, focusing on how ‘intake system longevity’ significantly influences resistance. We delve into comparative testing methods to assess UV damage, offering insights that can enhance product durability and performance. Understanding these ratings is key to navigating material choices, ensuring long-lasting applications in various industries.”

- Understanding UV Damage Resistance Rating: The Basics

- Intake System Longevity: A Key Player in UV Resistance Comparison Testing

- Methodology and Findings: Unlocking the Secrets of UV Damage Resistance Ratings through Comprehensive Testing

Understanding UV Damage Resistance Rating: The Basics

UV damage resistance rating is a critical metric that measures how well a material or product can withstand ultraviolet (UV) radiation over time. This rating is essential in various industries, particularly automotive and outdoor goods, where products are exposed to intense sunlight daily. Understanding this rating involves grasping the impact of UV light on different materials and how manufacturers test for resistance.

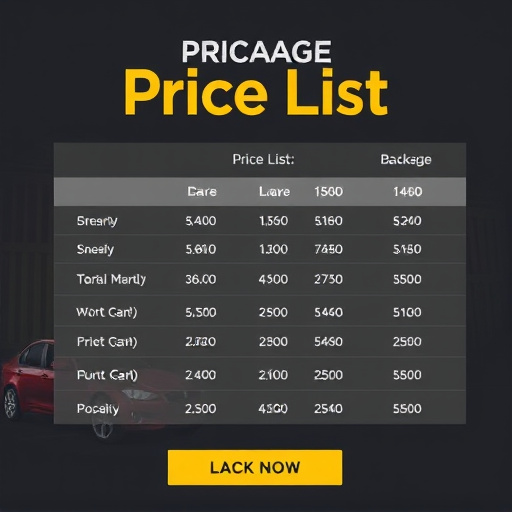

When we talk about UV damage, it’s crucial to know that UV light can degrade materials by breaking down chemical bonds, leading to changes in color, texture, and strength. To ensure product longevity, especially in exterior applications, manufacturers conduct rigorous testing under controlled conditions simulating real-world exposure. This intake system comparison testing involves exposing samples to specific UV levels over extended periods, mimicking years of weather exposure. As a result, these tests provide valuable data for consumers and professionals to make informed decisions when choosing materials or products that will maintain their quality and integrity over time in the face of UV radiation.

Intake System Longevity: A Key Player in UV Resistance Comparison Testing

In the realm of UV damage resistance ratings, one often-overlooked aspect is the intake system longevity. When comparing different materials or products, it’s crucial to consider how well their intake systems hold up against prolonged exposure to ultraviolet (UV) radiation. This is because the intake system—be it for a vehicle, building, or any other application—serves as a critical barrier, protecting the inner components from harmful UV rays.

In comparison testing, examining the intake system longevity becomes paramount. Over time, UV exposure can cause degradation, leading to leaks or reduced efficiency. Products with superior intake systems are expected to demonstrate enhanced durability, thereby ensuring better performance and extended service life. Thus, for any thorough assessment of UV resistance, evaluating the intake system’s ability to withstand UV damage is an indispensable step.

Methodology and Findings: Unlocking the Secrets of UV Damage Resistance Ratings through Comprehensive Testing

Comprehensive testing methodologies are essential for unlocking the secrets behind UV damage resistance ratings. This involves subjecting various materials and products to rigorous simulations of ultraviolet (UV) radiation exposure, mimicking real-world conditions over extended periods. The testing process includes controlled environments with precise UV intensity and duration, ensuring consistent results. Researchers then analyze the impact on different components, particularly those within an intake system, which are often vulnerable to UV degradation.

Through this method, scientists can compare longevity and performance across multiple materials. The findings reveal critical insights into material stability, colorfastness, and structural integrity under UV stress. This data is invaluable for manufacturers, enabling them to make informed decisions when developing products designed to withstand prolonged sun exposure, ensuring superior durability and maintaining aesthetic appeal over time.

UV damage resistance ratings are crucial for evaluating the durability of materials, particularly in outdoor applications. Through comprehensive intake system longevity comparison testing, we’ve uncovered valuable insights into how different products stand up against UV exposure. By understanding the basic principles behind these ratings and the role of the intake system in overall resistance, consumers can make informed decisions when selecting materials that offer superior protection against UV damage. This knowledge empowers folks to choose products that not only endure but also preserve their initial quality for longer periods.